In the intricate world of sensors and automation, ultrasonic sensors are pivotal components, seamlessly integrating into various technological applications and significantly enhancing their functionality. These sensors, utilizing the power of ultrasonic waves to detect objects, measure distance, and perceive environmental alterations, have permeated many industries, becoming indispensable in crafting advanced, efficient, and intelligent systems.

In this exploration, we will traverse the multifaceted applications of ultrasonic sensors, delving into how they have been ingeniously implemented across different industries, thereby shaping and optimizing processes, enhancing user experiences, and paving the way for innovations that once seemed beyond reach.

Contents

- What is an Ultrasonic Sensor?

- Key Components and Their Functions

- Brief on Types of Ultrasonic Sensors

- Core Benefits of Using Ultrasonic Sensors

- Accuracy and Reliability

- Non-Contact Detection

- Versatility in Various Environments

- Automotive Industry

- Industrial Applications

- Medical Field

- Environmental Monitoring

- Case Studies

- Autonomous Parking Systems

- Smart Waste Management

- Medical Diagnostics with Ultrasonography

- Challenges and Considerations

- Sensing Limitations

- Environmental Factors

- Interference and Cross-talk

- Installation and Calibration

What is an Ultrasonic Sensor?

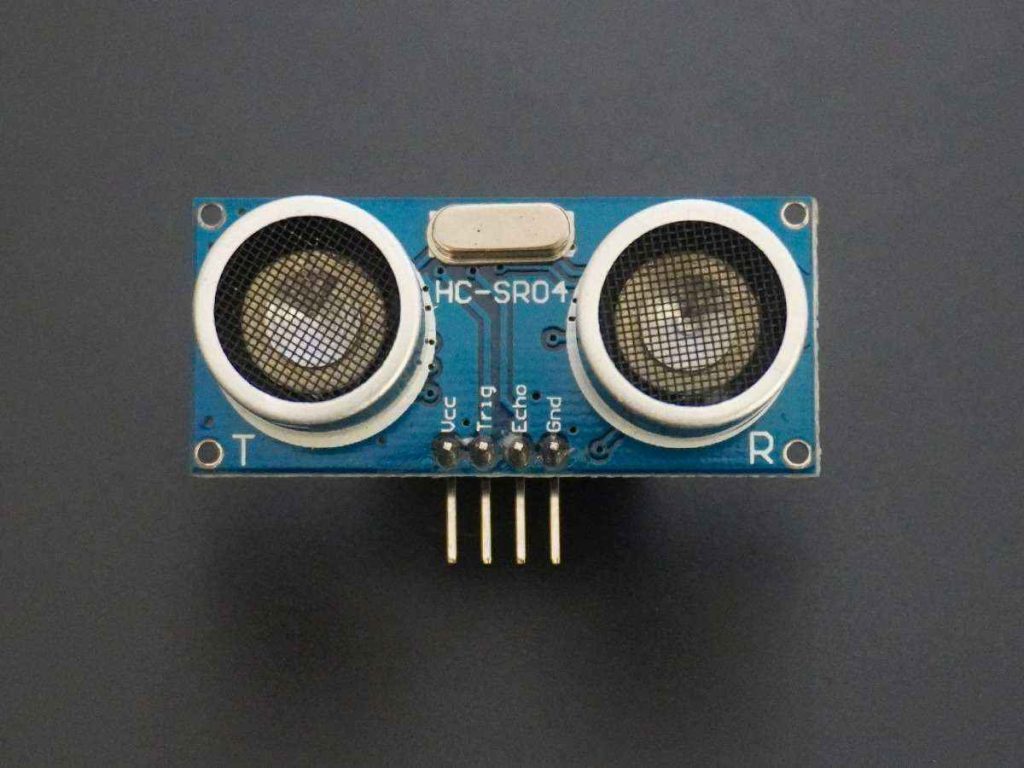

Definition and Basic Working Principle: An ultrasonic sensor is a device that utilizes ultrasonic sound waves to detect and measure an object’s distance and/or presence. These sensors operate on the principle of echolocation, similar to how bats or submarines navigate and see obstacles.

Key Components and Their Functions

Transducer: The transducer is responsible for converting electrical energy into sound waves (during emission) and the reflected sound waves into electrical energy (during reception).

Central Processing Unit (CPU): The CPU processes the signal the transducer receives, calculating the time lapse between emission and reception of the wave and determining the distance to the object.

Output Module: Depending on the sensor type, the output module translates the processed signal into a relevant output, such as an electrical signal, which other systems can utilize for further processing or triggering actions.

Power Supply: This component provides the necessary electrical power for the sensor.

Housing: The housing encases the components, providing protection and often directing the ultrasonic waves.

Brief on Types of Ultrasonic Sensors

Ultrasonic sensors can be broadly categorized based on their applications and configurations:

Single Transducer Sensors: Utilize a single transducer to emit and receive ultrasonic waves, commonly used in proximity sensing and distance measuring.

Array Transducer Sensors: Employ an array of transducers to provide a wider detection range or to enhance detection capabilities, often used in applications requiring detailed mapping or imaging.

Through-Beam Sensors: Use separate emitter and receiver units to detect objects that pass between them, commonly used in counting or object detection applications.

Reflective Sensors: Utilize the same unit to emit and receive sound waves, measuring the reflection off of objects to determine distance or presence.

Different types of ultrasonic sensors find their utility across various applications, each offering unique advantages and capabilities, which we will explore further in the subsequent sections, delving into their practical implementations across industries.

Core Benefits of Using Ultrasonic Sensors

Ultrasonic sensors have carved out a significant niche in various technological and industrial domains, attributed to their myriad benefits catering to different application needs. Let’s delve into some of the core advantages that have propelled the widespread adoption of ultrasonic sensors across diverse platforms and environments.

Accuracy and Reliability

Ultrasonic sensors stand out for their accuracy in distance measurement and object detection. By calculating the time interval between sending the ultrasonic wave and receiving the echo, they provide precise distance measurements, which remain largely unaffected by color, transparency, or shiny surfaces, ensuring reliable data in various scenarios.

Non-Contact Detection

One of the pivotal advantages of ultrasonic sensors is their ability to detect objects and measure distances without requiring physical contact with the sensed materials. This non-contact detection is crucial in applications involving fragile, hazardous, or sterile materials, ensuring safety, minimizing risk, and maintaining the integrity of both the sensor and the material.

Versatility in Various Environments

Ultrasonic sensors exhibit great versatility, functioning effectively in different environmental conditions. Whether deployed in dusty industrial settings, outdoor environments with varying light conditions, or applications involving mist and vapor, ultrasonic sensors maintain functionality, providing consistent and reliable data, even when optical sensors might struggle.

Automotive Industry

In automotive technology, ultrasonic sensors enhance safety, convenience, and innovation. Some of the key applications include:

Parking Assistance: Utilizing ultrasonic sensors to detect obstacles and calculate distances, aiding drivers in parking vehicles safely and accurately.

Collision Avoidance: Implementing sensors to detect potential collisions and alert drivers or trigger automatic braking systems.

Autonomous Vehicles: Employing ultrasonic sensors to navigate, detect obstacles, and facilitate safe and efficient autonomous driving.

Industrial Applications

Ultrasonic sensors find extensive applications in various industrial settings, contributing to automation, safety, and process optimization:

Level and Distance Measurement: Monitoring levels of liquids or solids in tanks and measuring distances to objects in industrial environments.

Object Detection: Identifying the presence or absence of objects on production lines or conveyor belts.

Safety and Security Systems: Deploying sensors in safety and security systems to detect unauthorized access or potential hazards.

Medical Field

In the medical field, ultrasonic sensors are instrumental in diagnostics, monitoring, and ensuring the smooth operation of medical devices:

Ultrasonography: Utilizing ultrasonic waves to create images of internal body structures for diagnostic purposes.

Fluid Level Monitoring in Medical Devices: Ensuring consistent fluid levels in dialysis machines.

Air Bubble Detection in IV Lines: Detecting air bubbles in intravenous lines to prevent air embolism.

Environmental Monitoring

Ultrasonic sensors play a crucial role in monitoring various environmental parameters and ensuring the well-being of ecosystems:

Water Level Monitoring: Keeping track of water levels in bodies of water to prevent flooding or to monitor drought conditions.

Wildlife Tracking and Monitoring: Utilizing sensors to track and monitor wildlife without physical intervention.

Weather Station Applications: Employing ultrasonic sensors to measure wind speed and direction in weather stations.

Case Studies

Exploring real-world applications and success stories provides tangible insights into the practicality and impact of ultrasonic sensors across various domains. Let’s delve into a few case studies highlighting innovative implementations and tangible benefits of ultrasonic sensor applications.

Autonomous Parking Systems

In the automotive industry, ultrasonic sensors have revolutionized parking systems. For instance, in smart parking solutions, ultrasonic sensors detect vehicles’ presence or absence in parking spots, transmitting data to a centralized system that guides drivers to available spaces, thereby optimizing parking management and enhancing user experience.

Smart Waste Management

In urban management, smart waste management systems utilize ultrasonic sensors to monitor the fill levels of waste bins. This data is transmitted to a central server, which then optimizes waste collection routes for sanitation crews, ensuring efficient resource utilization, reduced fuel consumption, and improved sanitation services.

Medical Diagnostics with Ultrasonography

Ultrasonic sensors have been pivotal in advancing medical diagnostics through ultrasonography. For example, in prenatal care, ultrasonography provides:

- Non-invasive imaging of fetuses.

- Enabling medical professionals to monitor health development and detect potential anomalies.

- Ensuring timely interventions and improved healthcare outcomes.

Challenges and Considerations

While ultrasonic sensors offer many benefits and have proven to be instrumental in various applications, it is also imperative to acknowledge the challenges and considerations that come with their implementation.

Sensing Limitations

Ultrasonic sensors may experience limitations in sensing objects with highly irregular surfaces or those that absorb ultrasonic waves. Ensuring that the sensor is suitable for the specific materials and conditions of the application is crucial.

Environmental Factors

Factors such as temperature, humidity, and ambient noise can influence the performance of ultrasonic sensors. Implementing compensating mechanisms or choosing sensors designed to withstand specific environmental conditions is vital.

Interference and Cross-talk

In applications with multiple ultrasonic sensors, interference and cross-talk between sensors can pose challenges. Employing sensors with different operating frequencies or implementing software solutions to manage sensor operation sequences can mitigate these issues.

Installation and Calibration

Ensuring accurate and reliable readings often requires meticulous installation and calibration of ultrasonic sensors. Considerations regarding sensor placement, angle, and calibration procedures are pivotal to ensure optimal performance.